In modern robotics and precision machinery, harmonic drive technologies have emerged as a cornerstone for achieving high-precision motion control and compact mechanical designs. These drives are characterized by their near-zero backlash, high torque-to-weight ratio, and exceptional repeatability, making them ideal for applications ranging from industrial automation to medical devices. PICEA MOTION, a leading innovator in precision harmonic drive systems, has leveraged extensive R&D expertise and world-class manufacturing equipment to refine these technologies, ensuring reliability and high performance in both domestic and international markets. Understanding the capabilities and operational principles of harmonic drives is essential for engineers and designers aiming to optimize performance in complex systems.

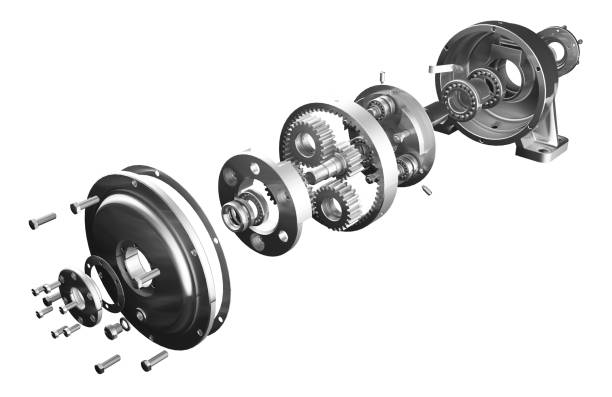

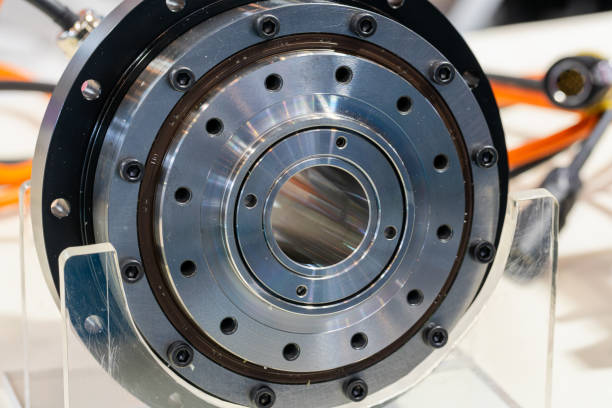

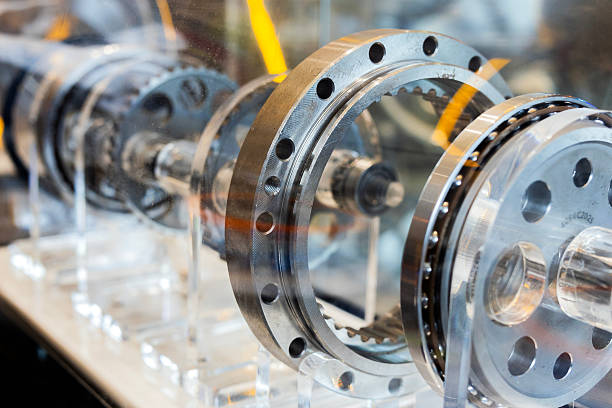

The essence of harmonic drive technologies lies in the interaction between the circular spline, flexspline, and wave generator. The flexspline deforms elastically as the wave generator rotates, producing highly accurate motion transmission without the mechanical backlash commonly associated with conventional gear systems. This design allows for compact and lightweight solutions while delivering high torque output, a critical requirement for applications such as robotic arms and articulated joints. PICEA MOTION integrates advanced engineering practices and rigorous quality control to ensure that each harmonic drive achieves precise tolerances, providing consistency in high-demand environments.

The performance and durability of harmonic drives are closely linked to material quality and manufacturing precision. High-strength alloys and carefully treated components minimize wear and fatigue, even under continuous operation. PICEA MOTION has invested in cutting-edge processing and testing equipment imported from leading global suppliers, coupled with an industrial robot engineering laboratory, allowing for sophisticated manufacturing and inspection processes. This approach ensures that harmonic drives meet stringent performance benchmarks while maintaining the longevity and reliability necessary for high-cycle robotic applications.

Feature | Harmonic Drive Technologies | Conventional Gear Systems |

Backlash | Near-zero, ideal for precision applications | Larger, affecting positional accuracy |

Torque-to-Weight Ratio | High, supports compact and lightweight designs | Moderate, often bulkier and heavier |

Repeatability | Excellent, supports complex robotic motion | Limited, prone to cumulative errors |

Maintenance Frequency | Moderate, with proper lubrication | High, frequent inspection required |

Flexibility in Mechanical Design | High, allows multi-axis compact integration | Low, restricts design possibilities |

This comparison underscores the superiority of harmonic drive technologies for applications demanding precision, compactness, and reliability. The innovative design of PICEA MOTION's drives allows engineers to achieve motion control that is difficult to replicate with conventional gearing solutions.

Harmonic drives have become a critical component in robotics, communication equipment, medical instruments, and testing and analysis machinery. In robotic systems, their high torque density and minimal backlash enable precise articulation of joints, supporting sophisticated automation tasks. PICEA MOTION's products are widely adopted in these sectors, benefiting from the company's strong R&D collaborations with the University of Tokyo and the University of Tsukuba, which continuously push the envelope of harmonic drive technologies. By integrating advanced materials, precise engineering, and innovative design, harmonic drives facilitate compact, efficient, and highly controllable robotic systems.

Maintaining the optimal performance of harmonic drives involves careful monitoring of load conditions, lubrication, and alignment. Overloading or exposure to harsh environmental conditions can compromise the lifespan of the drive. Regular inspection and precise alignment ensure consistent torque transmission and motion accuracy. PICEA MOTION's harmonic drives are engineered with robust designs that distribute stress evenly, allowing for extended operational cycles even in demanding robotic and industrial applications. Proper operational protocols not only preserve mechanical integrity but also optimize performance and reliability throughout the system's life.

Harmonic drive technologies continue to evolve in response to the increasing complexity of automation and robotics. Integration with sensors, advanced motor controllers, and feedback systems enhances precision and allows real-time adjustments during operation. PICEA MOTION remains at the forefront of these advancements, incorporating innovative manufacturing techniques and high-level engineering practices that enable seamless integration of harmonic drives into next-generation automation systems. The versatility and adaptability of these drives position them as critical components in advanced robotics, where compact design and high precision are indispensable.