Harmonic waveform generators are at the heart of advanced robotic systems, particularly when it comes to designing compact robots with high precision, smooth movement, and efficient power transmission. These generators create the strain waves that drive harmonic gears, facilitating the conversion of rotational motion into high torque with minimal backlash. The compactness and efficiency of harmonic waveform generators allow for the creation of smaller, more versatile robots, capable of performing intricate tasks in limited spaces. In industries ranging from healthcare to manufacturing, compact robots equipped with harmonic drives are revolutionizing how tasks are automated, making robots more adaptable, lightweight, and capable of operating in constrained environments.

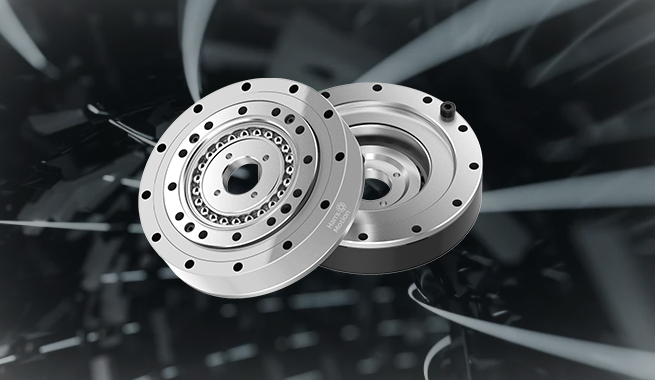

Harmonic waveform generators work by generating a strain wave that deforms a flexible gear (the flex spline) to mesh with a circular spline. This design allows harmonic drives to deliver high torque in a very small footprint, making them ideal for applications where size and weight are critical. In compact robot designs, these generators ensure that motors remain small, yet powerful enough to achieve the necessary movements for precise control. This reduction in size without sacrificing performance opens up new possibilities for mobile robots, service robots, and even medical robots, where the design constraints demand both compactness and functionality.

Compact robotic joints require both precision and power, often in a very confined space. Harmonic waveform generators play a pivotal role in enabling the precise, backlash-free movement required in these joints. The wave-like motion generated by the harmonic waveform generator ensures smooth operation, which is essential for applications like robotic arms, surgical robots, and industrial automation systems that need to perform repetitive, high-accuracy tasks without errors. This lack of backlash, combined with high torque output, enables robots to execute delicate movements in highly sensitive environments.

In traditional gear systems, backlash can cause deviations and inaccuracies, especially when the robot needs to repeat movements or handle sensitive materials. However, the harmonic waveform generator's unique mechanism eliminates this issue, making it ideal for high-precision tasks such as those performed by robots in surgery or semiconductor manufacturing. This precise control is especially important in compact robots, as the size restrictions mean that every component must be finely tuned for optimal performance. By ensuring that compact robots can perform with the same level of precision and reliability as larger, more complex robots, harmonic waveform generators are essential for improving robot design.

One of the most significant challenges in robot design is achieving miniaturization without compromising on performance. The compact design of harmonic waveform generators directly contributes to this goal, enabling the development of smaller robots that can still handle high-torque tasks. The inherent compactness of the harmonic drive system allows for the reduction of the overall robot size, as the drivetrain components—such as the motors and gears—take up much less space than traditional systems. This miniaturization is critical in industries where robots need to operate in constrained spaces, such as medical robots that perform minimally invasive surgeries or service robots working in tight office or home environments.

Furthermore, because harmonic waveform generators enable such efficient power transmission, they ensure that these small robots can perform tasks that traditionally required larger systems. The combination of small size and high torque makes it possible for robots to move swiftly and carry out a wide variety of tasks with precision, all while occupying minimal physical space. In applications like warehouse automation or robotic logistics, this feature helps create robots that can navigate narrow aisles and tight spaces, delivering the power and precision required without taking up valuable floor space.

The efficiency of a robot’s drivetrain is essential not only for its performance but also for its longevity and overall energy consumption. Harmonic waveform generators help improve the efficiency of robotic systems by minimizing energy losses during power transmission. Unlike traditional gear systems that can experience significant energy losses due to friction and backlash, harmonic drives ensure that more of the motor's energy is transmitted to the robot's moving parts, maximizing efficiency. This is particularly important for mobile robots, where battery life and power consumption are key factors in performance.

In addition to their energy efficiency, harmonic waveform generators also contribute to the overall reliability of robotic systems. Their design, which reduces the number of parts involved in power transmission, results in fewer points of potential failure. This contributes to higher reliability and less frequent maintenance, which is especially beneficial in applications where robots are required to perform continuous or long-term operations, such as in manufacturing or healthcare environments. The combination of energy efficiency, reduced wear and tear, and improved reliability ensures that robots equipped with harmonic waveform generators perform optimally over longer periods, which is essential for industries relying on continuous operations.

As robotic systems continue to evolve, the need for compact yet powerful robots will grow, especially as industries increasingly rely on automation in confined or complex environments. Harmonic waveform generators are poised to play a key role in shaping the future of robot design by enabling robots to become even more compact, efficient, and versatile. Advances in materials science and manufacturing technologies are likely to further improve the performance of harmonic waveform generators, making them even more reliable and capable of handling even more demanding tasks.

The trend towards increasingly capable and efficient compact robots is already seen in areas like medical robotics, where surgeons rely on robotic arms equipped with harmonic drives for precision surgery. In the future, we can expect even smaller, more advanced robots that are capable of performing tasks in previously inaccessible environments, from inside human bodies to remote space exploration. The ability of harmonic waveform generators to support such high-performance capabilities in small packages will be a driving force behind the next generation of robotic designs. With the continued evolution of harmonic waveform technology, robots will become smaller, smarter, and more efficient, paving the way for a future where robotics are integrated seamlessly into all aspects of human life.