In recent years, humanoid robotics has gained tremendous momentum, driven by advancements in artificial intelligence, precision mechanics, and control systems. A humanoid robot, unlike conventional robots, requires a high level of dexterity, balance, and precision to replicate human-like movement. The harmonic reduction gear has emerged as one of the most critical components that makes this possible. Known for its high torque capacity, compact size, and precise motion control, the harmonic reduction gear allows humanoid robots to achieve smooth and reliable performance across various tasks.

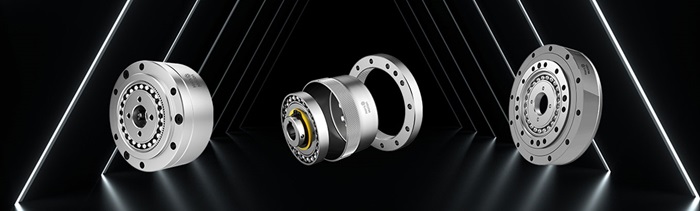

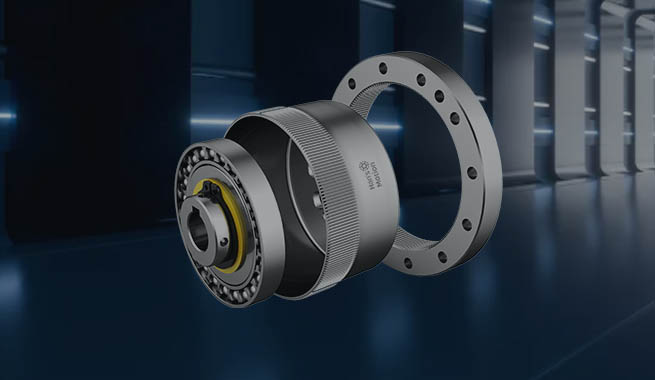

The superiority of harmonic reduction gear lies in its unique design, which uses the elastic deformation of a flexible spline to achieve speed reduction and torque transmission. This structure allows for zero backlash, exceptional accuracy, and a lightweight build—all essential features for humanoid robots that must handle delicate tasks and maintain balance while moving. Unlike traditional gear systems, harmonic reduction gear offers unmatched efficiency in joint control, enabling humanoid robots to mimic natural human movements with higher stability and smoother motion.

When it comes to humanoid robotics, not all gear systems perform equally. Below is a comparison between harmonic reduction gear and conventional gear mechanisms.

Feature | Harmonic Reduction Gear | Traditional Gear Systems |

Backlash | Near zero, ensures smooth motion | Noticeable backlash, affects precision |

Size and Weight | Compact and lightweight, ideal for humanoid joints | Bulkier, increases robot weight and volume |

Torque-to-Weight Ratio | High, provides strong performance with less mass | Lower, requires larger systems for same torque |

Motion Precision | Extremely accurate, supports delicate operations | Limited, prone to errors in positioning |

Durability under Repetition | Long lifespan in repetitive humanoid movements | Shorter lifespan, higher maintenance needs |

This comparison highlights why harmonic reduction gear has become the preferred choice for humanoid robotics, especially when precision, stability, and lightweight performance are critical factors.

PICEA Motion is a leader in the field of precision harmonic gear drives. With a registered capital of 50 million RMB and a strong R&D foundation, PICEA Motion has built an industrial robot engineering laboratory and introduced world-class testing and processing equipment. The company's close cooperation with the University of Tokyo and the University of Tsukuba demonstrates its strong ties between industry and research. Over the years, PICEA Motion has obtained multiple invention patents and software copyrights, earning recognition such as the Industrial Design "Red Sails Award", the Golden Finger Innovation Product Award, and the World Robotics Congress's Most Innovative Product Award.

With more than 300 customers worldwide, PICEA Motion's harmonic reduction gear products are widely used in robotics, communication equipment, medical devices, and testing systems. Their advanced technology provides humanoid robots with the high precision, durability, and efficiency necessary to meet the growing demands of this field.

As humanoid robots move closer to mainstream applications in service, healthcare, manufacturing, and personal assistance, the demand for reliable motion systems will only increase. Harmonic reduction gear technology is not just a mechanical component—it is the backbone of humanoid robotics, enabling machines to perform complex human-like tasks with agility and accuracy. With its commitment to "Innovative Craftsmanship" and "sophisticated craftsmanship", PICEA Motion continues to lead the way in developing high-value solutions for robotics. Its vision is clear: to become the most trusted expert in precision harmonic drive technology worldwide, empowering humanoid robots to achieve their full potential in the future of intelligent automation.