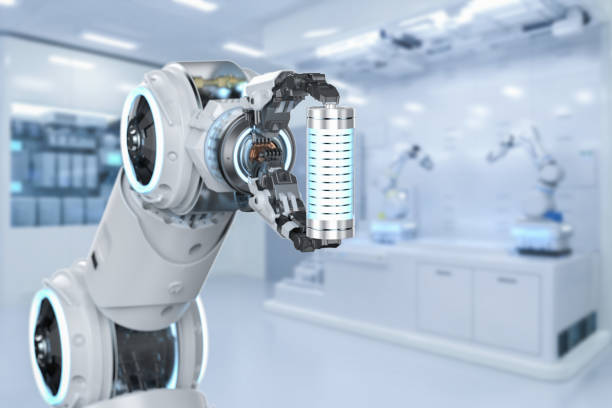

In the rapidly advancing field of robotics, the demand for high precision, compact size, and efficiency in motion systems has never been greater. Among the most critical components enabling these advancements are harmonic drives. Known for their unique ability to deliver zero backlash, high torque capacity, and excellent positioning accuracy, harmonic drives in robotics have become the cornerstone of modern automation and robotic system design.

Robots require actuators and gear systems that can deliver reliable motion while maintaining accuracy under dynamic loads. Traditional gear systems often struggle with backlash and limited torque density, which can compromise precision tasks. Harmonic drives, by contrast, operate on a flex spline and wave generator principle, which eliminates backlash and ensures consistent torque output. This makes them highly suited for robotic arms, humanoid robots, and autonomous systems that require repeatable accuracy in every movement. Their compact structure further allows engineers to design lightweight robots without sacrificing performance, a feature that is critical in fields like medical robotics and aerospace.

To understand the impact of harmonic drives in robotics, it is important to compare them with conventional transmission systems such as planetary gears and spur gears.

Feature | Harmonic Drives in Robotics | Traditional Gear Systems |

Backlash | Near zero, ensuring high accuracy | Noticeable, can affect precision tasks |

Torque-to-Weight Ratio | Very high, compact design | Lower ratio, requires larger size |

Positional Accuracy | Excellent, suitable for demanding applications | Moderate, limited in high-precision tasks |

Durability | High, with long service life under load | Good but wear increases backlash |

Suitability for Robotics | Ideal for arms, joints, and humanoid robots | More suitable for less demanding systems |

This comparison highlights why industries ranging from manufacturing to medical technology increasingly adopt harmonic drives over traditional alternatives.

The adaptability of harmonic drives allows them to be integrated into a variety of robotic systems. In industrial robots, they are used in articulated arms for welding, assembly, and inspection due to their precise positioning. In collaborative robots, harmonic drives ensure safe and smooth movements, enabling robots to work alongside humans without risk. In medical robotics, such as surgical assistants, the accuracy and low noise of harmonic drives are vital to delicate procedures. Even in communication equipment and testing devices, the ability of harmonic drives to operate consistently under high stress adds significant value to performance reliability.

One of the reasons harmonic drives in robotics have reached such a high level of advancement lies in the continuous collaboration between manufacturers and research institutions. Companies with strong R&D capacity have introduced world-class processing and testing equipment to refine precision. By working closely with universities such as the University of Tokyo and the University of Tsukuba, industry players combine academic research with practical application, accelerating innovation in robotic drive systems. These efforts not only lead to new patents and software innovations but also ensure that harmonic drive technology evolves in response to the growing demands of global robotics.

As robotics continues to integrate into more industries, the importance of harmonic drives will only expand. Future robots will demand even smaller, lighter, and more efficient motion systems capable of operating in complex environments. From space exploration to next-generation healthcare, harmonic drives are positioned to remain at the heart of robotic evolution. With ongoing advancements in materials science, engineering precision, and digital integration, their performance will continue to set new benchmarks for robotic mobility and intelligence.