In the world of robotics and automation, precision and efficiency are key components in ensuring optimal performance. One technology that has significantly contributed to these advancements is the harmonic drive, which when paired with a robot gearbox, can provide unparalleled levels of torque density, precision, and lightweight design. PICEA MOTION, a leader in the development of harmonic drives, has successfully integrated these high-performance systems into robotic applications, enhancing motion control and operational efficiency.

Harmonic drives, with their unique ability to offer high torque density in a compact form, have revolutionized the way robot gearboxes are designed and function. By utilizing the principles of elastic deformation, harmonic drives allow for the efficient transfer of power in a smaller, lighter package compared to traditional gear mechanisms. This is especially advantageous for robots that require both compactness and high performance, such as those used in industrial automation and medical applications.

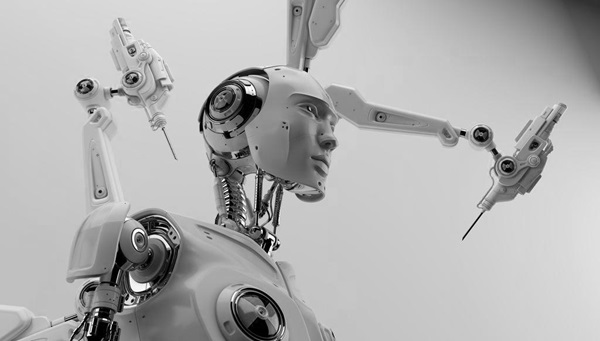

The combination of harmonic drives with robot gearboxes significantly improves motion control. The high precision offered by harmonic drives ensures that robots can execute movements with minimal backlash, translating to more accurate and responsive actions. This is particularly crucial in applications where precision is paramount, such as robotic arms used for assembly, surgery, or delicate handling tasks. With the ability to deliver consistent and smooth motion, harmonic drives allow robot gearboxes to function at their peak, providing exceptional repeatability and stability during operation.

Another key advantage of using harmonic drives in robot gearboxes is the reduction in size and weight. Traditional gearbox designs often require bulky components to achieve high torque outputs, whereas harmonic drives can provide the same level of performance while keeping the overall system lightweight. This reduction in weight not only enhances the mobility of robots but also contributes to energy efficiency. For mobile robots or drones, lighter systems can increase operational time and range, offering greater flexibility in various applications.

The widespread adoption of harmonic drives in robotics is driven by their ability to meet the exacting demands of modern automation systems. These drives offer exceptional torque transmission capabilities, making them ideal for use in robotic systems that require high precision and control. When integrated into a robot gearbox, the harmonic drive ensures that the robot can execute complex tasks with high accuracy, even under load.

In industrial automation, where robots often operate for extended hours under constant strain, the longevity and durability of the harmonic drive play a vital role in maintaining the system's performance. Unlike traditional gears, which can suffer from wear and tear over time, harmonic drives are designed to handle continuous high-load applications with minimal degradation. This makes them a preferred choice for applications such as automotive assembly lines, electronics manufacturing, and packaging.

Furthermore, harmonic drives offer a unique advantage in minimizing backlash, which is a common issue in traditional gearbox systems. Backlash occurs when there is a gap between the gears, leading to a loss in accuracy and potential errors in positioning. With harmonic drives, the elimination of backlash results in smoother and more precise motion, which is crucial for tasks that require fine manipulation and exact positioning.

When it comes to the specific advantages of harmonic gearboxes, several factors stand out. One of the most notable benefits is their compact design. Traditional gear systems require multiple stages to achieve the desired reduction ratio, often resulting in larger, heavier assemblies. Harmonic gearboxes, on the other hand, can provide significant reduction ratios in a much smaller and more lightweight package. This compactness makes them ideal for use in smaller robots or applications where space is limited, such as collaborative robots (cobots) or medical robots used in confined environments like operating rooms.

In addition to space savings, harmonic gearboxes are also highly efficient. They can achieve high reduction ratios with minimal energy loss, making them particularly useful in energy-conscious applications. This high efficiency ensures that robots can operate longer without requiring excessive power, improving overall system performance. Whether in industrial settings or precision applications, the efficiency of harmonic gearboxes ensures that robots can maintain consistent, high-performance operation without overheating or wasting energy.

Another advantage is the versatility of harmonic gearboxes. They can be easily integrated into a wide range of robotic systems, from heavy-duty industrial robots to lightweight medical robots. Their ability to operate effectively across various environments and tasks, from high-precision to high-torque applications, makes them an essential component in many robotics platforms.

As robotics continues to evolve, the integration of harmonic drives with robot gearboxes is expected to play an even more significant role in future advancements. With increasing demands for robots that are not only precise but also adaptable and energy-efficient, harmonic drives are poised to lead the way in driving innovation. The combination of high torque density, low weight, and superior precision will enable robots to take on more complex and challenging tasks across industries, from manufacturing and logistics to healthcare and beyond.

The ongoing development of harmonic drives is likely to include further improvements in materials and manufacturing techniques, allowing for even greater efficiency and performance. For example, the use of advanced composites and lightweight materials in the construction of harmonic gearboxes could further reduce weight while maintaining strength and durability. Additionally, with the rise of artificial intelligence and machine learning, harmonic drives could be integrated into more intelligent robotic systems that can learn, adapt, and optimize their movements in real-time.

The future of robotic automation is undeniably tied to the continued evolution of harmonic drives and their seamless integration with robot gearboxes. By combining the strengths of these technologies, PICEA MOTION and other industry leaders are setting the stage for a new generation of robots that are faster, smarter, and more capable than ever before.