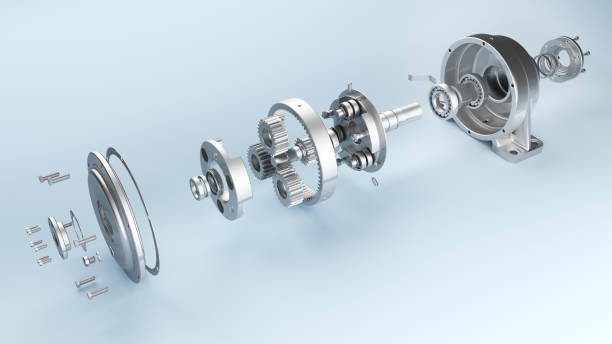

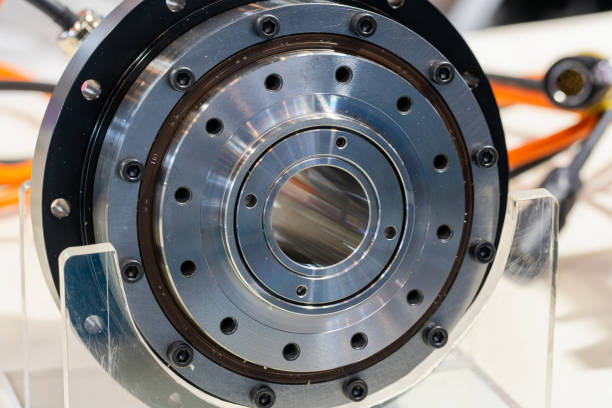

The harmonic reduction gear is a specialized transmission system designed to achieve high accuracy and efficiency in motion control. Its working principle is based on the elastic deformation of a thin, flexible component, known as the flexspline, which interacts with a circular spline and a wave generator. This unique mechanism enables smooth torque transmission with almost zero backlash. Unlike conventional gear systems, the harmonic drive design allows for precise control of motion, making it suitable for demanding applications such as robotics, medical devices, and testing equipment. The principle ensures that even under high loads and compact structures, performance remains stable and highly reliable.

PICEA MOTION focuses on structural innovation to deliver advanced harmonic drive solutions. By integrating state-of-the-art processing and testing equipment, the company has optimized each element of the gear's construction. The flexspline is engineered for durability under repeated deformation, the wave generator provides accurate input control, and the circular spline ensures stability and load-bearing capacity. These structural innovations allow the harmonic reduction gear to achieve compact dimensions while maintaining strength and performance, which is critical for modern robotics, communication systems, and electromechanical equipment.

The combination of technical precision and structural innovation results in significant performance benefits. The following table provides a clear comparison of harmonic reduction gear performance against traditional gear systems in engineering applications.

Feature | Harmonic Reduction Gear (PICEA MOTION) | Conventional Gear Systems |

Backlash | Near zero | Noticeable, reduces accuracy |

Torque-to-Weight Ratio | High, enabling compact design | Lower, requires bulkier components |

Motion Accuracy | Extremely precise | Limited, prone to deviations |

Durability | Long lifespan under continuous use | Shorter, requires frequent upkeep |

Application Versatility | Robotics, medical, testing, telecom | Narrower range of applications |

These performance advantages make harmonic drives a cornerstone in industries requiring precision and reliability. In robotics, for example, harmonic reduction gears enable smooth, accurate movements critical for humanoid robots. In medical equipment, they support delicate operations where even minor inaccuracies are unacceptable. Testing and analysis systems also rely on this gear for consistent results, reinforcing its wide adaptability.

Despite its strengths, the development of harmonic reduction gear faces ongoing challenges, such as balancing compactness with higher torque capacity, and advancing material performance to improve efficiency. PICEA MOTION meets these challenges with its strong R&D team and collaboration with renowned institutions like the University of Tokyo and the University of Tsukuba. The company holds numerous invention patents and software copyrights, and its products have earned awards such as the Industrial Design "Red Sails Award" and the World Robotics Congress's Most Innovative Product Award.

Moving forward, PICEA MOTION continues to embody its philosophy of "Innovative Craftsmanship," striving to enhance product value and reliability. With more than 300 global customers, the company is dedicated to shaping the future of precision engineering and reinforcing its reputation as a trusted expert in harmonic reduction gear solutions.