A harmonic gear drive, as the name suggests, is a mechanical transmission system that uses harmonic vibrations to achieve gear transmission. It is a key component in countless robotic applications. While it appears simple, its operation is quite unique. This gear system generates oscillations during operation but can provide a high torque-to-weight ratio and unparalleled precision, even though it does indeed oscillate. It is a precise transmission device that can achieve small size, high reduction ratios, and high torque, making it widely used in precision instruments, robotics, aerospace, and other fields.

What is a Harmonic Gear Drive?

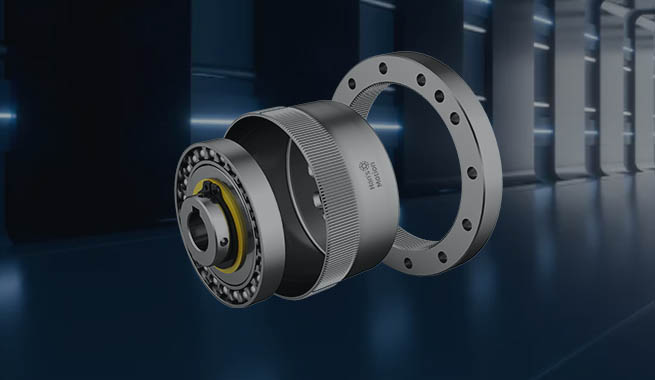

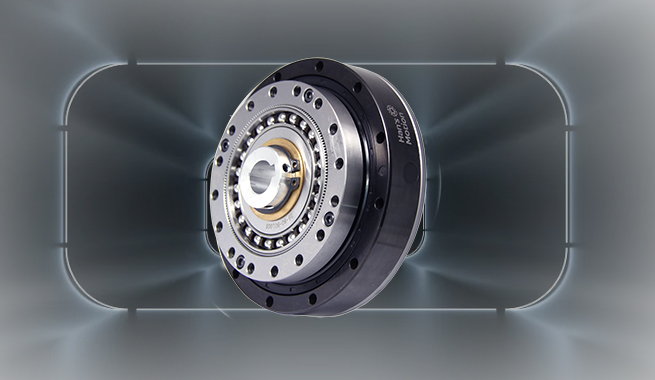

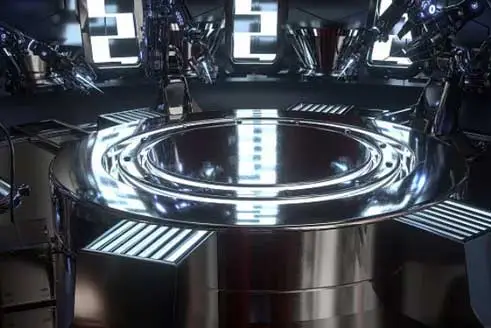

A harmonic gear drive is a mechanical transmission device based on the principle of harmonic vibrations. It consists of a movable wheel, flexible gear, and fixed gear. The harmonic generator converts the unidirectional rotation of the input shaft into an output shaft with harmonic characteristics, thereby achieving gear reduction. Compared to traditional gear drives, the harmonic gear drive offers higher reduction ratios, greater output torque, and ultra-small size and lightweight features.

Characteristics of Harmonic Gear Drive

Harmonic gear drive has the following characteristics:

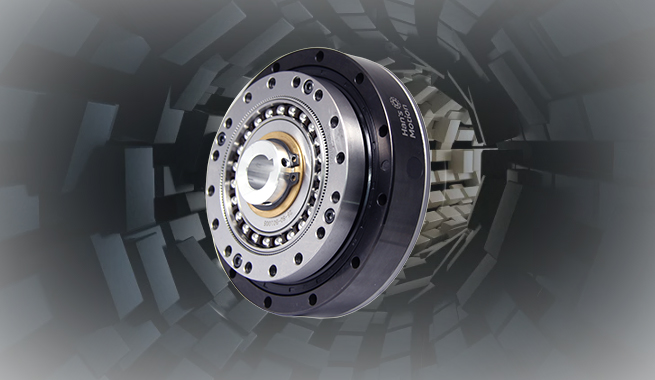

High Precision: By utilizing the bending deformation of the flexible gear for transmission, harmonic gear drive provides high precision with minimal error.

High Reduction Ratio: Harmonic gear drive can achieve a large reduction ratio, typically greater than 50:1.

High Torque: The output torque of a harmonic gear drive can reach very high values, meeting the requirements for large power transmission.

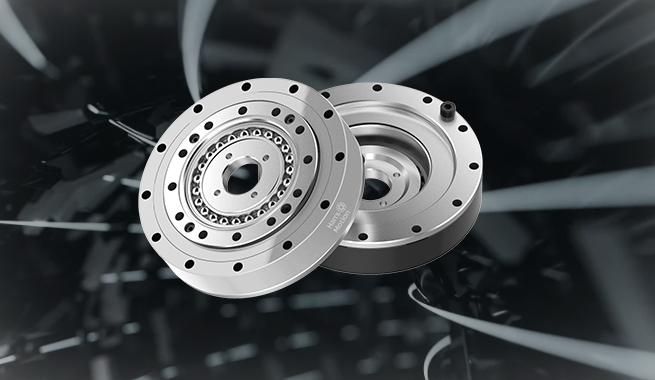

Ultra-small Size: Due to the use of flexible gears and a compact structural design, harmonic gear drive has ultra-small sizes and lightweight features, making them suitable for applications in space-constrained environments.

Working Principle of Harmonic Gear Drive

The working principle of a harmonic gear drive is to use a harmonic generator to convert the unidirectional rotation of the input shaft into an output shaft with harmonic characteristics, thereby achieving gear reduction.

Specifically, the harmonic generator consists of an eccentric shaft, rollers, and a pressure plate. When the input shaft rotates, the eccentric shaft causes the position of the rollers to change periodically, leading to pressure variations between the rollers and the flexible gear. This causes the flexible gear to undergo bending deformation.

When the flexible gear deforms, the secondary gears on the fixed gear will engage with it and rotate in the direction of the reduction ratio. Since the position of the rollers in the harmonic generator changes periodically, the output shaft also exhibits harmonic characteristics. By adjusting the parameters of the harmonic generator, the reduction ratio and output torque of the harmonic gear drive can be modified.

Applications of Harmonic Gear Drive in Industrial Automation

Thanks to its significant advantages in transmission precision and efficiency, harmonic gear drive is increasingly used in industrial automation. They play an indispensable role in machine tools, robotics, aerospace, and medical devices, providing powerful support for various high-precision equipment. With continuous technological advancements, harmonic gear drive will showcase their exceptional performance in even more fields in the future.