The performance of robot gearboxes is highly dependent on the materials used in their construction and the manufacturing processes that bring these components to life. As robots become more sophisticated, the need for precision, reliability, and lightweight designs in robot gearboxes has increased significantly. PICEA MOTION, a leader in the development of harmonic drives, ensures that its robot gearboxes meet the demands of high-performance robotic applications by leveraging advanced materials and manufacturing techniques.

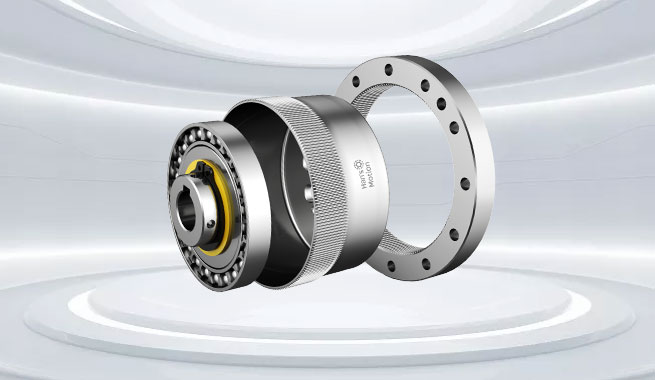

Selecting the right materials for robot gearboxes is essential to achieve high efficiency, durability, and precision. The materials used directly affect the performance, weight, and longevity of the gearbox, which in turn impacts the overall robot system. For robot gearboxes, PICEA MOTION focuses on high-quality metals and composites that provide both strength and lightweight characteristics. Materials such as hardened steel, aluminum alloys, and titanium alloys are commonly used in gearbox construction due to their excellent strength-to-weight ratios and high resistance to wear.

Hardened steel, for instance, is often selected for its ability to withstand high loads and its resistance to abrasion, making it ideal for gear teeth that endure continuous motion and heavy torque. Aluminum alloys are favored for their lightweight nature, which is crucial for mobile robots that need to conserve energy and move efficiently. Titanium alloys, while costlier, offer exceptional strength and corrosion resistance, which is particularly valuable in specialized robots, such as those used in medical or aerospace applications.

Moreover, the use of advanced composite materials is becoming more prevalent in the design of robot gearboxes. Composites like carbon fiber-reinforced polymers offer superior strength while reducing weight, further enhancing robot mobility and efficiency. By integrating these materials, robot gearboxes can perform more effectively in demanding applications, such as high-precision industrial robots, collaborative robots (cobots), and medical robots.

The manufacturing processes used to create robot gearboxes are just as important as the materials themselves. A gearbox's performance, durability, and precision are largely determined by the quality of its manufacturing. PICEA MOTION employs cutting-edge manufacturing techniques, such as precision casting, CNC machining, and 3D printing, to ensure the highest quality standards in robot gearbox production.

Precision casting is widely used in the production of robot gearboxes, particularly for complex parts that require high precision. This process allows for the creation of intricate designs with minimal material waste, reducing the need for extensive post-production machining. CNC (Computer Numerical Control) machining is another critical process for producing robot gearboxes with exact specifications. This method ensures that every component, such as gears and shafts, meets tight tolerances, which is vital for maintaining the smooth and precise operation of the gearbox.

In addition to these traditional techniques, additive manufacturing, or 3D printing, is becoming an important part of gearbox production. With the ability to create highly complex, customized parts, 3D printing is increasingly used in the prototyping phase of gearbox design. It allows for rapid iteration and testing of new designs before moving to full-scale production. For certain applications, 3D printing also enables the creation of lightweight structures that are impossible to achieve with traditional manufacturing methods.

By utilizing these advanced manufacturing processes, PICEA MOTION ensures that its robot gearboxes are not only highly functional but also durable and precise, capable of handling the high demands of modern robotic systems.

Heat treatment is a crucial step in the manufacturing process that significantly enhances the durability and performance of robot gearboxes. Heat treatment processes like quenching, tempering, and case hardening are used to alter the physical properties of metals, improving their strength, hardness, and wear resistance. These treatments are particularly important for robot gearboxes, which often operate under high-stress conditions, where components like gears and shafts need to maintain their integrity over long periods of time.

For example, gears made from steel are often subjected to a heat treatment process called carburizing, where carbon is diffused into the surface layer to create a hard outer shell. This hard surface layer helps to resist wear, while the inner core remains tough and shock-resistant. Another common heat treatment is induction hardening, where a metal is rapidly heated and then cooled to increase its surface hardness. This process is especially useful for gears that require exceptional wear resistance in high-load applications.

By applying heat treatment to robot gearbox components, PICEA MOTION ensures that its gearboxes are capable of withstanding the continuous stresses and harsh conditions found in industrial, medical, and other high-performance robotic applications. This enhances the overall reliability and longevity of the gearbox, reducing the likelihood of failure and ensuring consistent performance over time.

The field of materials science and manufacturing technology is continually evolving, and future innovations promise to bring even more advanced materials and processes to the production of robot gearboxes. One area of innovation is the development of more advanced composite materials that offer even better strength-to-weight ratios and greater durability. For example, next-generation carbon fiber composites and advanced polymers could provide robots with even greater mobility and efficiency, especially in applications where weight is a critical factor, such as mobile robots and drones.

Furthermore, the integration of smart materials into robot gearboxes could open up new possibilities for adaptive and self-monitoring systems. Smart materials, which can respond to changes in their environment or load, could enable robot gearboxes to adjust their performance in real-time, optimizing for factors like energy efficiency and load-bearing capacity. This would be especially valuable in robots that operate in dynamic environments where conditions can change rapidly.

Advancements in manufacturing technologies, such as the use of nanotechnology and artificial intelligence in the production process, could also lead to even more precise and efficient robot gearbox production. These technologies have the potential to revolutionize how robot gearboxes are designed, produced, and optimized, leading to even more efficient, durable, and adaptable systems.

The materials and manufacturing processes used in the construction of robot gearboxes play a critical role in ensuring their performance, durability, and precision. With advanced materials such as hardened steel, aluminum alloys, and composites, combined with cutting-edge manufacturing techniques like precision casting, CNC machining, and 3D printing, robot gearboxes can meet the demanding requirements of modern robotics and automation systems. As the field of materials science and manufacturing continues to evolve, the future holds even greater possibilities for enhancing the performance and capabilities of robot gearboxes.