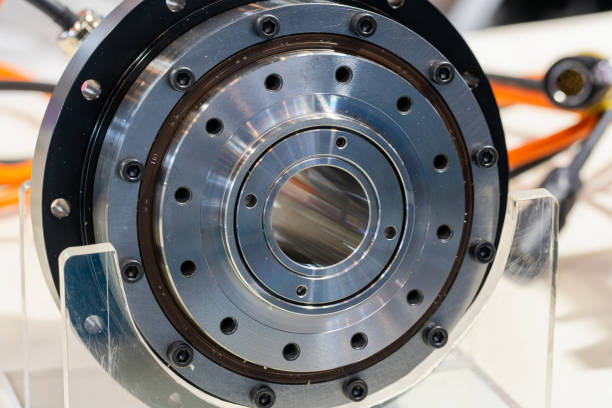

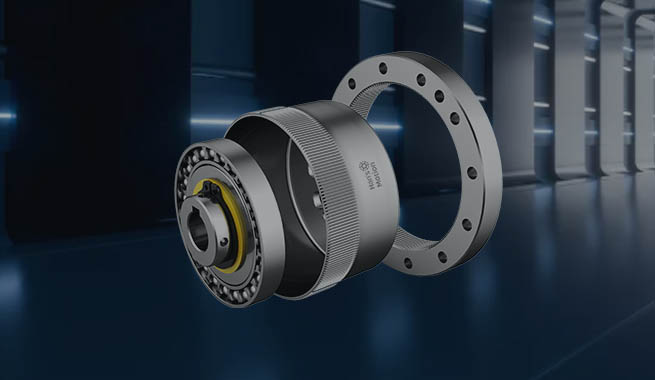

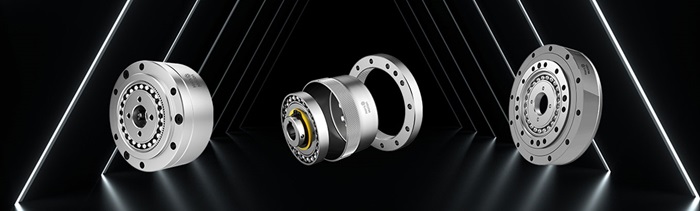

At the heart of every harmonic reduction gear lies a precise arrangement of harmonic drive components that ensure accurate and reliable motion control. These include the wave generator, flexspline, and circular spline. The wave generator deforms the flexspline, creating a wave that engages with the circular spline. This unique interaction allows the harmonic drive to transmit torque efficiently while maintaining a compact form factor. PICEA MOTION has invested in world-class processing and testing equipment, allowing each component to meet strict precision requirements. By mastering the production of these harmonic drive components, the company ensures durability, high efficiency, and performance suitable for demanding robotics, medical devices, and testing equipment applications.

The harmonic drive reduction ratio is a critical parameter that determines how much the output speed is reduced relative to the input. Harmonic drives can achieve high reduction ratios within a single stage, providing significant torque multiplication without increasing the size of the system. This capability is particularly advantageous in robotics, where space constraints are critical but high torque output is required. PICEA MOTION's harmonic reduction gears are designed to optimize the harmonic drive reduction ratio for maximum efficiency, ensuring that robotic arms and other electromechanical systems operate with precision and stability.

Feature | Harmonic Reduction Gear | Traditional Gear Reducer |

Backlash | Near zero | Moderate to high |

Compactness | Very compact | Larger footprint |

Torque Density | High | Moderate |

Precision | High | Lower |

Maintenance | Minimal | Moderate to frequent |

This table highlights the advantages of harmonic reduction gear systems over traditional gear reducers. The ability to combine compact design with high torque density makes harmonic drives indispensable for advanced robotics and precision machinery. PICEA MOTION focuses on producing harmonic drives that outperform conventional systems in reliability, precision, and longevity.

The performance of harmonic drives heavily relies on the quality of materials used for harmonic drive components. PICEA MOTION selects high-strength materials for the flexspline and circular spline, ensuring that they can withstand repeated deformation while maintaining structural integrity. Advanced manufacturing techniques, combined with meticulous quality control, allow PICEA MOTION to maintain consistency across each production batch. This commitment to quality supports the high harmonic drive reduction ratio capabilities and ensures that each harmonic reduction gear performs reliably under continuous operation.

PICEA MOTION has positioned itself as a leader in the field of harmonic reduction gear technology. Through collaborations with the University of Tokyo and the University of Tsukuba, the company has strengthened its research capabilities, continuously innovating in the design and production of harmonic drives. With over 300 customers worldwide and numerous awards for technological innovation, PICEA MOTION demonstrates its dedication to precision engineering. By focusing on the optimization of harmonic drive components and harmonic drive reduction ratio, the company ensures that its products meet the evolving needs of robotics, medical equipment, communication devices, and industrial automation.