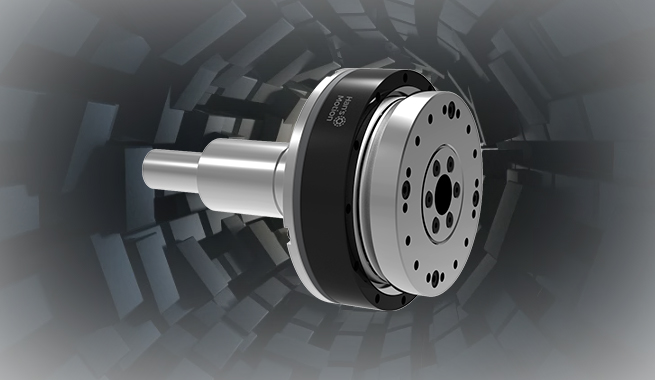

A harmonic gear reducer is a precision transmission device that leverages the unique properties of strain wave gearing to convert flexible components into highly rigid and accurate motion systems. Unlike traditional gears that rely on rigid meshing teeth, harmonic gear reducers use a wave generator to deform a flexible gear, creating a system that is both compact and capable of achieving high torque output with exceptional precision. The basic components of a harmonic gear reducer are the wave generator, the flex spline, and the circular spline. The wave generator, powered by a motor, creates a strain wave that deforms the flex spline, which then meshes with the circular spline. This interaction allows for an efficient transmission of torque without the backlash issues typically associated with traditional gears.

The ability of the flex spline to deform allows the harmonic gear reducer to achieve high reduction ratios, which are essential for applications requiring precise speed and torque control. The wave generation mechanism ensures that the gear teeth mesh smoothly, reducing friction and enabling quieter, more reliable operation. This characteristic makes harmonic gear reducers ideal for tasks that demand both high torque and high accuracy, such as in robotics, aerospace, and automated systems. The combination of compact size, high performance, and minimal backlash is what makes harmonic gear reducers stand out in the world of precision engineering.

Harmonic gear reducers offer several distinct advantages over traditional gearing systems, particularly in precision applications. One of the most significant benefits is their ability to provide high torque in a compact form factor. Unlike conventional gearboxes, which may require large, bulky components to achieve high torque, harmonic gear reducers use their unique design to pack a powerful punch in a much smaller package. This is particularly important in industries like robotics, where size constraints are common, and the demand for high torque and precision is critical.

Another key advantage of harmonic gear reducers is their ability to eliminate backlash. Backlash, or the slight movement that occurs when gears fail to mesh precisely, can be detrimental to the accuracy of a system, especially in high-precision applications. By using a flexible spline that allows for smooth meshing, harmonic gear reducers effectively reduce or eliminate backlash, ensuring that robotic arms, surgical robots, or automated machinery can perform with high accuracy and repeatability. This makes harmonic gear reducers a perfect fit for applications such as CNC machines, robotic joints, and servo motor systems, where precision is paramount.

The compact nature of harmonic gear reducers plays a crucial role in the miniaturization of robotic systems. As robots become smaller and more agile, there is an increasing demand for gear systems that are both powerful and compact. Harmonic gear reducers allow designers to meet this demand by providing a compact and efficient solution for motion control. The flexibility of the flex spline and the efficient torque transfer make it possible to design robots with smaller, more lightweight actuators while still achieving the required high torque and precision.

This is particularly important in medical robotics, where space constraints within the human body require compact and highly efficient components. Harmonic gear reducers are ideal for these applications because they provide the necessary power and precision in a much smaller form factor than traditional gear systems. Similarly, in drones or mobile robots, where size, weight, and agility are critical, harmonic gear reducers enable smooth and efficient motion in a small package. The flexibility to achieve high torque and precision in a compact design opens up a wide range of possibilities for robotics and automation in confined or challenging spaces.

Harmonic gear reducers are also widely used in automated systems, where high efficiency, precision, and reliability are essential for optimal performance. In automation, harmonic gear reducers help enhance the precision and responsiveness of machinery by reducing the mechanical play between gears and ensuring smooth, controlled motion. This is critical in industries such as semiconductor manufacturing, where even the smallest deviation in motion could lead to defects in production. The backlash-free operation of harmonic gear reducers ensures that automated systems can perform repetitive tasks with high accuracy over extended periods, leading to improved system efficiency and consistency.

Moreover, the high torque density of harmonic gear reducers means that automated systems can achieve greater power output without requiring large or heavy components. This helps maintain the efficiency and compactness of automated equipment, which is important in industries where space is at a premium. Whether used in conveyor systems, robotic arms, or other industrial robots, harmonic gear reducers enable smooth and reliable operation while reducing wear and tear on components. This extends the lifespan of the automation system and reduces maintenance needs, improving overall productivity and operational cost-effectiveness.

In conclusion, harmonic gear reducers are essential for the precise and efficient performance of modern robotic systems and automation. Their unique ability to convert flexibility into rigidity allows them to achieve high torque, minimal backlash, and compact designs, making them invaluable in applications ranging from medical robots to industrial automation. As technology advances, harmonic gear reducers will continue to shape the future of precision engineering, helping to create more efficient, smaller, and more powerful robotic systems.