In the rapidly expanding field of robotics, motion precision and compact transmission systems have become decisive factors for innovation. Among these technologies, the harmonic reduction gear stands out for its ability to deliver exceptional accuracy and reliability. Unlike conventional gear mechanisms, harmonic reduction gears leverage strain wave transmission to achieve near-zero backlash, high torque capacity, and superior repeatability. These unique advantages are why the technology is becoming an indispensable component in humanoid robots, industrial automation, and medical robotics.

PICEA MOTION, with its strong R&D foundation and international collaborations, has taken a leading role in refining and promoting harmonic reduction gear solutions. With over 300 customers worldwide, the company is helping shape the future of intelligent automation.

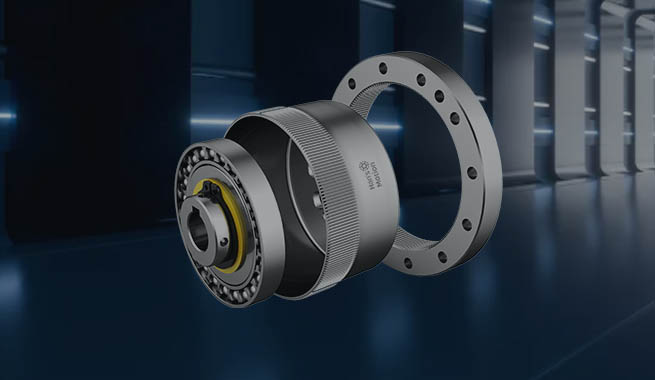

The importance of a harmonic reduction gear lies in its ability to integrate high torque transmission with a compact and lightweight design. For humanoid robots, this translates to fluid joint motion and improved balance, while in industrial robots, it enhances efficiency in repetitive and high-precision tasks. In addition, harmonic drives are widely applied in communication devices, testing and analysis systems, and medical equipment where reliability is paramount.

PICEA MOTION's expertise ensures that each product not only meets strict performance requirements but also adapts seamlessly to a wide range of robotics and electromechanical applications. By prioritizing quality and precision, the company continues to meet the growing demand for advanced robotic solutions.

The performance of a harmonic reduction gear is heavily influenced by the manufacturing technologies and material choices involved. PICEA MOTION has introduced world-class processing and testing equipment to ensure each component meets international standards. High-grade alloys and precisely engineered flexible components allow harmonic drives to sustain both high torque and long-term durability.

Through careful material selection and state-of-the-art processing, the company maintains superior consistency in its products. This commitment not only enhances reliability but also extends the service life of harmonic drives, providing significant value to customers in robotics and beyond.

One of the defining features of the harmonic reduction gear is the special tooth profile design that allows strain wave transmission to achieve precision beyond conventional systems. The geometry of the teeth ensures maximum surface contact, which minimizes backlash and enhances efficiency. Processing accuracy during gear manufacturing directly impacts the final product's motion smoothness and positioning reliability.

By integrating advanced machining techniques, PICEA MOTION optimizes tooth profile performance, resulting in drives that deliver consistent accuracy under demanding conditions. This attention to detail highlights why the company has earned industry recognition for technological innovation and product excellence.

Looking ahead, the role of the harmonic reduction gear in robotics is set to expand further. With humanoid robots entering mass production and industries worldwide accelerating automation, the demand for precision transmission systems will continue to grow. PICEA MOTION, guided by its philosophy of "Innovative Craftsmanship", is dedicated to advancing the performance and reliability of harmonic drives.

By combining research partnerships with institutions such as the University of Tokyo and the University of Tsukuba, along with continuous investments in engineering innovation, PICEA MOTION is positioned to remain a global leader. As strain wave transmission technology continues to evolve, harmonic reduction gears will be at the core of the robotics revolution, powering a future defined by intelligence, precision, and efficiency.