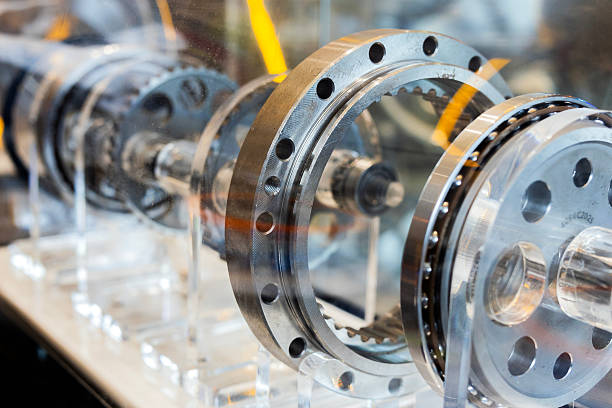

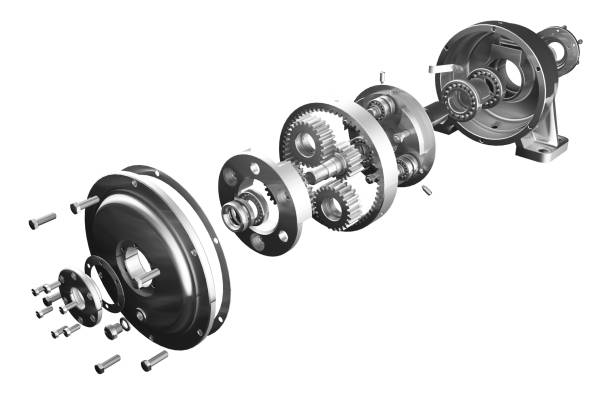

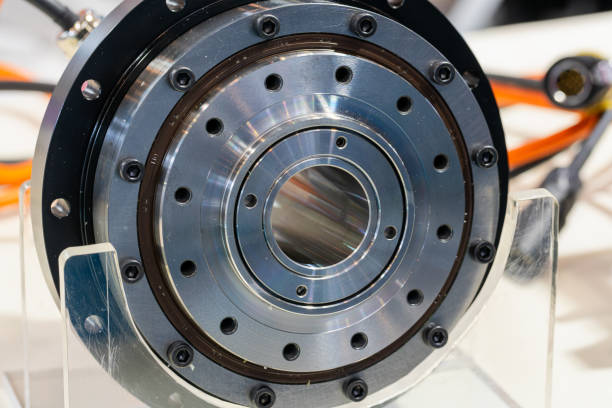

The foundation of harmonic drive technologies lies in the unique harmonic drive working principle, which differentiates it from conventional gear systems. A harmonic drive reducer consists mainly of three components: the wave generator, the flexspline, and the circular spline. When the wave generator deforms the flexspline, it creates a constant wave of motion that engages with the circular spline, resulting in smooth and precise torque transmission. This mechanism provides exceptional advantages such as near-zero backlash, high torque density, and compact design, which are critical for robotics and high-precision applications.

PICEA MOTION has invested heavily in advanced testing and processing equipment to ensure that its harmonic drive solutions maintain stability and accuracy under demanding conditions. By mastering the harmonic drive working principle, the company has developed products that meet the needs of robotics, communication equipment, and medical devices worldwide.

One of the most significant applications of harmonic drive technologies is in the robotics industry. Robots require highly accurate movements to perform delicate or repetitive tasks efficiently, and harmonic drives make this possible. With their ability to deliver smooth transmission and minimal backlash, harmonic drives allow robotic arms to perform with consistency and reliability.

PICEA MOTION's harmonic drive technologies have been widely adopted in robotic systems where precise control and compact design are essential. The company's commitment to innovation has earned it recognition such as the World Robotics Congress's Most Innovative Product Award, confirming its role as a leading contributor to advanced automation.

The performance of harmonic drives depends heavily on material quality and precision in manufacturing. PICEA MOTION utilizes world-class processing technology to achieve superior results. High-quality materials ensure that the flexspline maintains durability while allowing for the necessary deformation that enables motion transfer. This balance between strength and flexibility is critical to achieving long service life and consistent performance.

Through rigorous quality testing and continuous improvement, PICEA MOTION ensures that every product adheres to global standards. This focus on materials and precision is part of the company's philosophy of "Innovative Craftsmanship", which drives its pursuit of excellence in harmonic drive technologies.

Another distinguishing factor of PICEA MOTION is its commitment to research and collaboration. By working closely with leading institutions such as the University of Tokyo and the University of Tsukuba, the company strengthens the connection between industry and academia. This collaboration accelerates the development of new applications of harmonic drive technologies and ensures that the company remains ahead of technological trends.

These partnerships have helped PICEA MOTION secure multiple invention patents and software copyrights, highlighting its role as a pioneer in the industry.

The future of automation, robotics, and precision equipment will rely heavily on the continued advancement of harmonic drive technologies. As demands for accuracy, reliability, and efficiency grow across industries, harmonic drives will remain a cornerstone of innovation.

PICEA MOTION, with its strong R&D team and commitment to quality, is well-positioned to lead this progress. By adhering to its corporate philosophy of "sophisticated craftsmanship, the company continues to deliver value to its customers worldwide. To learn more about the future of harmonic gear drive reducers, visit PICEA MOTION.