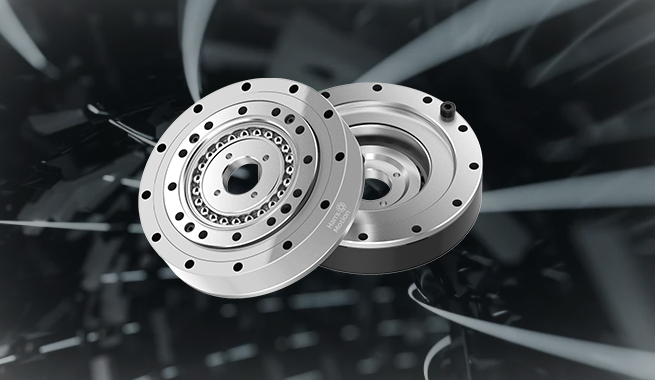

Harmonic waveform generators are crucial components in harmonic drive systems, responsible for initiating the strain wave mechanism that defines the functionality of these drives. The harmonic waveform generator works by generating a precise wave-like deformation, which is transferred to the flex spline gear, allowing it to mesh with the circular spline and transmit torque efficiently. This deformation is key to creating the high torque-to-weight ratio and precision that harmonic drives are known for. As a result, the harmonic waveform generator plays a pivotal role in ensuring that the drive system operates smoothly, with minimal backlash, high efficiency, and excellent positional accuracy. In the context of robotic systems and automated machinery, this relationship between the harmonic waveform generator and the harmonic drive ensures that robots can perform tasks with both precision and power, making them ideal for applications where accuracy and space constraints are critical.

The performance of a harmonic drive is directly tied to the waveform generation process, as the shape and characteristics of the generated strain wave impact how the gear system operates. The generator's ability to create a smooth and consistent wave deformation leads to reduced friction and more efficient torque transmission. This is crucial in systems where minimal mechanical losses are required, such as in high-precision robots or industrial automation systems. By enabling high-torque output in a compact form factor, the harmonic waveform generator allows harmonic drives to excel in environments where size and performance are both important factors.

Efficiency is a key aspect of harmonic drive performance, and the harmonic waveform generator plays a critical role in achieving this. Unlike traditional gear systems, where friction and backlash can reduce efficiency, harmonic drives rely on a smooth, continuous strain wave that helps minimize these issues. The harmonic waveform generator ensures that the wave is accurately formed and transmitted to the flex spline, enabling the gear system to transfer torque with minimal loss. This efficiency is particularly important in applications where energy consumption needs to be optimized, such as in robotics or mobile systems that rely on battery power.

By facilitating precise movement with minimal friction, the harmonic waveform generator contributes to the overall reduction of energy waste in the system. When harmonic drives are paired with high-efficiency motors, this synergy results in robotic systems that can operate for longer periods without overheating or draining power. The ability to maintain high efficiency also leads to lower wear and tear on the system, which in turn extends the lifespan of the drive. This is especially important in industries where long-term performance and reliability are necessary, such as in aerospace or medical robotics, where consistent functionality is a must.

One of the most defining characteristics of harmonic drive systems is their ability to achieve high precision with zero backlash, and the harmonic waveform generator is central to this ability. The smooth strain wave produced by the generator enables the gears to mesh without any gaps or play between the flex spline and the circular spline, eliminating backlash. This precision is essential in robotics, where even the smallest deviation can lead to significant errors in performance.

In contrast to traditional gears, where backlash can accumulate over time and lead to inaccuracies, harmonic drives offer a level of motion control that is crucial in high-precision tasks. For example, robotic arms that are used for delicate surgeries or high-precision manufacturing require exact movements that can only be achieved with backlash-free gearing systems. The harmonic waveform generator's ability to produce a strain wave with minimal deviation directly contributes to the drive system's ability to maintain precise control over the robot's movements, even in complex and dynamic environments.

Another significant advantage of harmonic waveform generators is their contribution to the compact nature of harmonic drive systems. In many applications, such as medical robots, drones, and small industrial robots, space is at a premium. The harmonic waveform generator's ability to create high-torque output in a compact form factor is a game-changer for designers looking to create smaller, more efficient robotic systems. The generator works in conjunction with the rest of the harmonic drive components to minimize the size and weight of the drive system while still delivering exceptional performance.

This is particularly advantageous in applications where space is constrained, such as inside the human body for minimally invasive surgery or in drone propulsion systems. The ability to achieve high torque output in such small packages is due in large part to the harmonic waveform generator's role in the strain wave process, making it a key enabler of miniaturization in robotic design. Compact harmonic drive systems are not only more versatile in their applications but also offer improved maneuverability and agility, which are essential in fields where flexibility and adaptability are paramount.

As technology continues to evolve, harmonic waveform generators are likely to see further improvements that will enhance the performance of harmonic drive systems. Innovations in materials, manufacturing techniques, and wave generation technology will enable even more efficient and reliable harmonic waveform generation. Future harmonic waveform generators may be able to produce even smoother strain waves, reducing friction and improving the precision of torque transmission even further.

The continued development of harmonic waveform generators will also play a significant role in the expansion of robotic applications. With ongoing advancements, we can expect even smaller, more efficient robots capable of performing highly complex tasks in increasingly restricted environments. As robotic systems become more integrated into industries like healthcare, logistics, and manufacturing, the importance of reliable and efficient harmonic waveform generation will only increase, allowing harmonic drives to maintain their role as a cornerstone of modern robotics and automation.

As the demand for smarter, more adaptable robotic systems grows, the harmonic waveform generator will remain a central player in ensuring these systems can deliver high performance in compact, efficient packages. With their ability to enable precise, high-torque, backlash-free motion in a small form factor, harmonic waveform generators will continue to be integral to the evolution of robotics and automation for years to come.