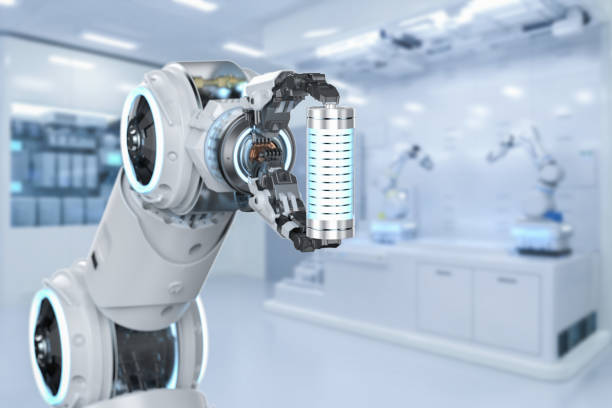

As robotics continues to evolve, the demand for high-precision, lightweight, and durable transmission solutions has never been greater. Among these, the harmonic drive robot system stands out as one of the most effective approaches to achieving smooth, accurate, and efficient motion. With its unique mechanical structure and engineering advantages, harmonic drives have become a cornerstone in industrial robots, service robots, and medical automation.

A harmonic drive robot integrates harmonic gear technology into its motion system to enhance precision, reduce backlash, and maintain compactness. Unlike conventional gear mechanisms, harmonic drives utilize the flexibility of the flexspline and the engagement with the circular spline to achieve higher torque density and smooth operation. This makes them an indispensable solution in applications where exact positioning, high repeatability, and reliability are critical. PICEA MOTION, with decades of accumulated expertise and strong R&D resources, provides harmonic drive solutions that meet the stringent requirements of modern robotics.

When evaluating the performance of a harmonic drive robot, it is essential to compare it with robots using conventional gear systems. The following table illustrates key differences:

Feature | Harmonic Drive Robot (e.g., PICEA MOTION) | Traditional Gear Robot |

Backlash Control | Near zero, ensuring high positioning accuracy | Noticeable backlash, reduced accuracy |

Size and Weight Efficiency | Compact and lightweight with high torque | Larger and heavier for similar torque |

Motion Smoothness | Smooth and vibration-free operation | Higher noise and vibration |

Service Life | Long life due to fewer moving parts | Shorter life with more mechanical wear |

Application Flexibility | Ideal for robotics, automation, and medical devices | Limited to less demanding applications |

This comparison highlights why the harmonic drive robot is becoming the standard in advanced robotic systems worldwide.

In the industrial sector, harmonic drive robots are widely deployed in assembly lines, welding, material handling, and precision machining. Their accuracy enables robots to work alongside humans in collaborative environments where safety and precision are paramount. By using harmonic drive technology, robots can achieve repeatability within microns, which is critical for tasks such as electronic component assembly or advanced manufacturing. With PICEA MOTION’s advanced production facilities and engineering laboratories, customers gain access to solutions that maximize productivity and minimize downtime.

The success of harmonic drive robots also depends on continuous technological advancement. Suppliers with strong R&D capabilities can push the boundaries of performance, ensuring drives remain efficient under demanding conditions. PICEA MOTION's partnerships with the University of Tokyo and the University of Tsukuba demonstrate the importance of research-driven innovation in this field. These collaborations allow the development of harmonic drive robots that not only meet current industrial needs but also anticipate future challenges in automation, AI-driven robotics, and next-generation medical equipment.

The long-term value of adopting harmonic drive robots lies in efficiency, reliability, and scalability. Their ability to deliver consistent precision significantly reduces the need for maintenance and minimizes costly downtime. In robotics and automation, where every millisecond of accuracy translates into higher production quality, these benefits are irreplaceable. By choosing advanced solutions from experienced manufacturers like PICEA MOTION, industries secure a path toward sustainable automation and enhanced competitiveness in global markets.